Vibrating Screen

![]() Home products

Stone crushing machine

Vibrating Screen

Home products

Stone crushing machine

Vibrating Screen

Vibrating Screen

- Reliable performance, low energy consumption

- Low noise, long life and high screening efficiency

- Simple structure, easy maintenance

- Great exciting force

Introduction to Vibrating Screen

There are two kinds of vibrating screens: the linear vibrating screen and the circular vibrating screen.

.jpg)

The linear screen is a kind of highly efficient screening facility. It has been widely used in mining, coal, smelting, building materials, fireproofing, light industry, chemical industry and others.

The circular vibrating screen is another new type highly efficient screening machine which makes circular movements. This type of vibrating screen applies the cylindrical eccentric shaft exciter. It has been widely used in materials screening in mining, building materials, traffic, energy resources, chemistry industry, etc.

Structure and Working Principle of Vibration Screen

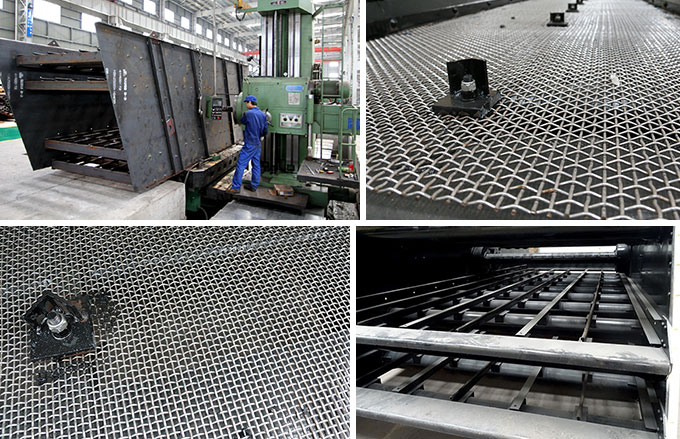

The linear screen is mainly composed of the screening box, the screening mesh, the vibration motor, electrical pedestal, vibration reduction spring and the rack.

1. The screening box: As the main component of the machine, made of pine wood or wood and soldered by steel plates with different degrees of thickness, certain strength and stiffness which is not easy to deform, it is used to keep the sieve smooth for normal screening.

2. Screening mesh: There are low carbon steel, copper, bronze and stainless steel wire type meshes.

3. Vibration motor: (usage and maintenance methods as shown in the instructions).

4. Electrical pedestal: When operators install the vibration motor, the connective screws should be tightened, especially during the first three trial days in case accidents occur.

5. Vibration reduction spring: preventing vibration from passing onto the ground and supporting the full weight of the screening box. When installed, the spring must be vertical to the ground.

6. The rack: composed of four pillars and two steel channels supporting the screening box; it should also be vertical to the ground while the two channels should be parallel to each other.

The linear vibrating screen is driven by two vibration motors. When the motors rotate simultaneously in the opposite direction, the exciting force produced by the eccentric block offsets in the direction parallel to axis and joins in the direction vertical to the axis. So the movement path is a straight line. The two motors form an angle to the screening deck. Under the exciting force and gravity, materials are thrown up forward by leaps and bounds for linear movement so as to achieve the goal of screening and classification .

The circular vibrating screen is mainly made up of the screening box, exciter, suspension (or supporting) device and motor, etc. The motor drives the exciter axis through the triangle belt. With the effect of the centrifugal inertia force caused by the imbalance of weight, the screening box starts vibrating. By changing the eccentric weight, different amplitudes can be achieved.

Features

The linear screen has the features of reliable performance, low energy consumption, low noise, long life and high screening efficiency. The circular vibrating screen features simple structure, great exciting force, high efficiency, low noise, durability, easy maintenance, safety, etc.

Note: If you're interested in the product, please submit your requirements and contacts and then we will contact you in two days. We promise that all your informations won't be leaked to anyone.

| Model | Sieve Layer | Sieve Area (㎡) |

Mesh Size (mm) |

Max.Feeding Size (mm) |

Processing capacity (m³/h) |

Vibrating Frequency (r/min) |

Double Amplitude (mm) |

Power (kw) |

Sieve Obliquity (°) |

Sieve Specification (mm) |

Dimensions (L×W×H) (mm) |

| 2YK1230 | 2 | 7.2 | 4-50 | 200 | 12-78 | 970 | 6 | 6P 7.5 | 20 | 1200×3000 | 3530×1885×920 |

| 3YK1230 | 3 | 10.8 | 4-50 | 200 | 13-80 | 970 | 6 | 6P 7.5 | 20 | 1200×3000 | 3675×1885×1320 |

| 2YK1237 | 2 | 8.88 | 4-50 | 200 | 15-86 | 970 | 6 | 6P 7.5 | 20 | 1200×3700 | 4230×1990×920 |

| 3YK1237 | 3 | 13.32 | 4-50 | 200 | 16-90 | 970 | 6 | 6P 7.5 | 20 | 1200×3700 | 4375×1990×1320 |

| 2YK1548 | 2 | 14.4 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 11 | 20 | 1500×4800 | 5355×2195×1030 |

| 3YK1548 | 3 | 21.6 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 15 | 20 | 1500×4800 | 6055×2195×1740 |

| 4YK1548 | 4 | 28.8 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 18.5 | 20 | 1500×4800 | 6195×2195×2120 |

| 2YK1854 | 2 | 19.44 | 5-80 | 200 | 32-312 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6515×2555×1370 |

| 3YK1854 | 3 | 29.16 | 5-80 | 200 | 32-312 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6655×2555×1750 |

| 4YK1854 | 4 | 38.88 | 5-80 | 200 | 32-336 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6790×2555×2130 |

| 2YK2160 | 2 | 25.2 | 5-100 | 200 | 50-475 | 970 | 6 | 6P 30 | 20 | 2100×6000 | 7200×2945×1580 |

| 3YK2160 | 3 | 37.8 | 5-100 | 200 | 50-475 | 970 | 6 | 6P 30 | 20 | 2100×6000 | 7340×2945×1980 |

| 4YK2160 | 4 | 50.4 | 5-100 | 200 | 50-497 | 970 | 6 | 6P 37 | 20 | 2100×6000 | 7490×2945×2380 |

| 2YK2460 | 2 | 28.8 | 5-100 | 200 | 65-550 | 970 | 6 | 6P 30 | 20 | 2400×6000 | 7200×3200×1580 |

| 3YK2460 | 3 | 43.2 | 5-100 | 200 | 70-620 | 970 | 6 | 6P 37 | 20 | 2400×6000 | 7340×3200×1980 |

| 4YK2460 | 4 | 57.6 | 5-100 | 200 | 80-680 | 970 | 6 | 6P 45 | 20 | 2400×6000 | 7490×3200×2380 |

| 2YK2866 | 2 | 31 | 5-100 | 200 | 70-650 | 970 | 6 | 6P 37 | 20 | 2800×5600 | 6950×3610×1790 |

| 3YK2866 | 3 | 47 | 5-100 | 200 | 80-700 | 970 | 6 | 6P 45 | 20 | 2800×5600 | 7130×3610×2270 |

| 4YK2866 | 4 | 62 | 5-100 | 200 | 90-750 | 970 | 6 | 6P 55 | 20 | 2800×5600 | 7300×3610×2750 |

| 2YK2873 | 2 | 39.2 | 5-100 | 200 | 70-680 | 970 | 6 | 6P 37 | 20 | 2800×6500 | 7850×3587×1790 |

| 3YK2873 | 3 | 58.8 | 5-100 | 200 | 80-720 | 970 | 6 | 6P 45 | 20 | 2800×6500 | 8025×3587×2270 |

| 4YK2873 | 4 | 58.8 | 5-100 | 200 | 90-950 | 970 | 6 | 6P 55 | 20 | 2800×6500 | 8200×3587×2750 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Note: If you're interested in the product, please submit your requirements and contacts and then we will contact you in two days. We promise that all your informations won't be leaked to anyone.